RIGGING - JULY 1997 DROP TESTS

Rigging Home >> Drop Tests >> July 1997 Drop TestsThe July 1997 tests were CMRU's first step in proving the validity of using tandem prusiks as a belay device for a rescue load -- that is, 210 kg, a load simulating the weight of a loaded litter and one litter attendant. The test simulated a one meter fall of the loaded litter and attendant, on three meters of line.

The belay line was a retired 7/16 inch (11 mm) low-stretch rescue rope. The load was attached to the belay line with a large aluminum locking D carabiner clipped into a bight formed by a double loop bowline knot (also known as a rescue bowline). For these tests, the "unit under test" was made of 8 mm low-stretch Edelrid accessory cord. The large and small Prusik loops were fashioned with a grapevine or double fisherman's knot.

For this set of tests, a mark (black electrical tape) was placed at the double-loop bowline and another mark was placed 3 meters away. Once the load was lifted about a meter off the ground, all slack was removed from the double-loop bowline by taking the load onto the belay line for about 20 seconds. Using the lifting line, the load was then lifted until the 3 meter mark on the belay line was at the "unit under test." The prusiks were then set by hand as a belayer would do if the raising/lowering system had been stopped. The load was then raised another meter and released, resulting in a 0.33 fall factor.

For the sake of consistency, the same person tied the double-loop bowline for each test; and the tandem prusik belay system was rigged by the same person for each test. As in the real world, the belay line ran from the tandem prusiks up through a Rock Exotica prusik-minding pulley and back to the ground. The prusik-minding pulley was attached to the main anchor by a large aluminum locking D carabiner. With the prusik belay system about 25 feet in the air, it was handy to have a bucket lift to use while setting the prusiks.

Prusiks tied from both old and new accessory cord were tested. The old prusiks were from the CMRU equipment racks and had been in use for about one year (mainly for practice sessions). They had not been subjected to severe abuse; the mantle material was just beginning to "fuzz". When not in use they had been stored in the CMRU truck, The new prusiks were made of cord taken right off the spool. They had never been used in the field.

During the tests, the weather conditions at the outdoor test site were clear with temperatures from the high 70's to mid 80's. The humidity was moderate to low and the wind was light.

Test Results

| Test # | Load (Kg) | Description of Unit Under Test | Runout Distance |

| 1 | 210 | Tandem Prusiks: 8mm material used 1 year. Dry | 9.75 in (25 cm) |

| 2 | 210 | Tandem Prusiks: 8mm material used 1 year. Dry | 14.75 in (37 cm) |

| 3 | 210 | Tandem Prusiks: 8mm material used 1 year. Dry | 9.75 in (25 cm) |

| 4 | 210 | Tandem Prusiks: 8mm material used 1 year. Wet | 22 in (56 cm) |

| 5 | 210 | Tandem Prusiks: 8mm material used 1 year. Wet | 18 in (46 cm) |

| 6 | 210 | Tandem Prusiks: 8mm material used 1 year. Wet | 14 in (36 cm) |

| 7 | 210 | Tandem Prusiks: 8mm new material. Dry | 7 in (18 cm) |

| 8 | 210 | Tandem Prusiks: 8mm new material. Dry | 7.6 in (19 cm) |

| 9 | 210 | Tandem Prusiks: new material. Wet | 14.25 in (36 cm) |

| 10 | 210 | Dog-n-Tails: 8mm material used 1 year. Dry | 12.6 in (32 cm) |

| 11 | 210 | Dog-n-Tails: 8mm new material. Dry | 6.9 in (17 cm) |

| 12 | 300 | Tandem Prusiks: 8mm material used 1 year. Dry * | 50.25 in (128 cm) |

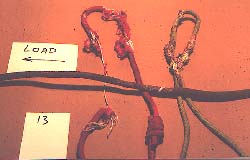

| 13 | 300 | Tandem Prusiks:

8mm material used 1 year. Dry * | 62.5 in (159 cm) |

| 14 | 300 | Tandem Prusiks: 8mm new material. Dry * | 49.5 in (126 cm) |

|

| Qualitatively, using a 210 kg mass (simulating a loaded litter and one attendant) the tandem-prusik belay system worked very well -- on dry or wet rope, with old or new prusik material. Runout (distance the belay line ran until it stopped) varied from 7 - 22 inches. However, using a 300 kg load (to simulate two litter attendants) was another matter. The 8 mm material of the shorter prusik essentially failed in all three drops and the load was stopped by only the longer prusik in two drops using old prusiks. Both prusiks failed in the third test using new prusik material! It appears new prusik material "grabs" quicker, resulting in shorter runout and a greater force. We also drop tested the dog 'n tails hitch and it held -- here too the newer material resulted in shorter runout. In addition, the tests gave us the opportunity to see how the double-loop (or rescue) bowline knot performed under a severe load. In each case, about 5 cm (2 inches) of extension was noted when the knot was loaded, but only about 1-2 cm more extension was caused by the shock load of the 0.33 fall factor drop. Even after the fall, the knot could be untied without difficulty. |

|

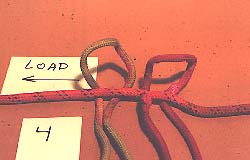

Test 4: 210 kg. load, used prusiks, wet

Test 4: 210 kg. load, used prusiks, wet

The used wet prusiks slid an average of 46 cm before catching the load while the used dry prusiks slid an average of 35 cm. |

||

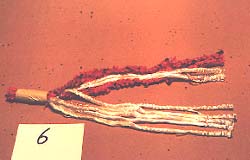

Test 6: 210 kg. load, used prusiks, wet

Test 6: 210 kg. load, used prusiks, wet

Although the mantle of the rope was badly damaged, the kern appeared unharmed. | ||

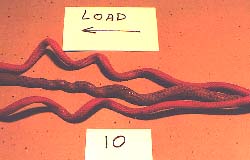

Test 10: 210 kg. load, used dog 'n tails, wet

Test 10: 210 kg. load, used dog 'n tails, wet

The dog 'n tails deformed the rope |

||

Test 11: 210 kg. load, new dog 'n tails, dry

Test 11: 210 kg. load, new dog 'n tails, dry

It was interesting that it was the center wraps of the dog 'n tails that caught the load. |

||

|

||

|

||

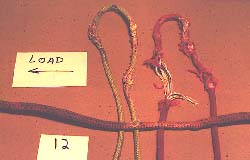

Test 14: 300 kg. load, new prusik, dry

Test 14: 300 kg. load, new prusik, dry

When the prusik material was new, both prusiks failed and the load bottomed out. |